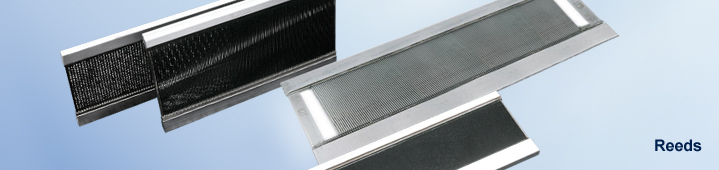

Reeds

Reed for Rapier Machine| Reed Water Jet Machine| Reed for Narrow Fabrics & Label Weaving|

Reeds for Weaving Preparation

Reeds are created by us in all required execution and dimensions suitable for conventional as well as modern weaving machineries. The heart of reed i.e. flattened strip is manufactured in our in-house capacity. We use wires that reduce friction and are super smooth ensuring weaving without yarn breakages. To minimize yarn breakages further we design them in oval shape. Reeds manufactured by us are framed on highly precised machine for high accuracy in spacing of individual dents with even length. Further finishing of reeds is done to ensure smooth weaving of fabrics. Reeds are designed with special care to ensure that the fabric reaches its perfection.

Soldered reeds are manufactured with special care to achieve uniform soldering in both types strips i.e. mild steel and stainless steel (INOX), care has been taken to ensure non-breaking and evenness of binding. Special adhesives are applied to reeds for bonding of aluminum / stainless steel (INOX) profiles to ensure better strength and durability.

Reeds can be manufactured in double binding for both top & bottom or top or bottom for maximum potentiality. Reeds for weaving preparatory are manufactured in both types of dents i.e. flat and round dents, to give more durability special hard chrome process being carried out with great smoothness. Dents are available in high carbon as well as stainless steel (INOX).

The adopted techniques and systems maintained by us permits ease in weaving and thereby avail defectless fabrics. Reeds are suitable to use on high profile machines manufactured by Picanol, Sulzer, Tsudakoma, Panter, Vamtex, Toyoda etc.

We also provide the product as per your requirements and desired configuration.

Flat Steel Reeds

Flat Steel Reeds produced by us in all required execution and dimensions mostly suitable for every machines. Such types of Reeds are soldered with special care to achieve uniform soldering and accurate spacing of individual dents and care has been taken for smooth weaving of fabrics.

| Flat Steel Reeds' Specification | |||

| Dent Frequency | Width of Dent | Material of Dent | Bonding |

| 4D/cm to 60D/cm | 2, 2.5, 3, 4, 5, 6, 8 mm | Mild Steel, High Carbon Steel, Stainless Steel | Chemical Bonded / Tin Soldered |

Reeds for Metallic Cloth

These Reeds are made from the best quality flattened wire material in Mild Steel, High Carbon Steel, Stainless Steel (AISI 430, AIS1316) in wire width ranges from 2mm to 4mm. These Reeds are bonded with special resins for providing better strength, flexibility and uniformity. Such types of Reeds are used for metallic cloth and screen printing fabrics.

Double Reeds

The Reeds are manufactured from smooth and super finished flattened wire in Mild Steel, Carbon Steel and Stainless Steel (AISI 430. AISI 316). Reeds can be produced with dent width in 2.2, 2.5, 3mm. These Reeds are used in Terry Fabrics and Special cloth.

Reed for Sulzer Machine

Reed produced from the first quality materials - Mild Steel, High Carbon Steel, Stainless Steel (AISI 430, AISI 316) with standard measures 4mm dents width. Reeds are glued in special Aluminium / Stainless Steel channel for the bottom and Aluminium profile at the top to ensure better strength and regularity. Reeds can be manufactured in Single or Double Binding for both top & bottom, for better flexibility& durability.

Reed for Rapier Machine

Reeds for Rapier Machine as per specifications are manufactured for better quality weaving. These Reeds are also available in S.S. material. Provisions can also be made for Stainless Steel & Mild Steel channels instead of Aluminium, which is suitable for high speed machines.

Reed Water Jet Machine

We also manufacture Reeds suitable for high speed looms including Water Jet Machine. Special care is to be taken in designing of such Reeds to provide uniform dent wire finish for higher weaving efficiency. Reeds made of Stainless Steel (AISI 430, AISI 316) with 2.2, 2.5, 2.8, 3mm wire width, are manufactured to provide more durable option. We can supply the Reed in both types of bonding i.e. Chemical Bonding and Tin Soldered.

Reed for Narrow Fabrics & Label Weaving

Both types of Reed can be manufactured using Mild Steel, High Carbon Steel & Stainless Steel with both Soldered and Chemical bonded, as specified by the customer. We are well established to manufacture all types of Reeds for Narrow Fabrics and Label Weaving.

| Reed for Narrow Fabrics' Specification | |||

| Dent Frequency | Width of Dent | Material of Dent | Bonding |

| 4D/cm to 24D/cm | 3, 4, 5, 6 mm | High Carbon Steel, Stainless Steel | Tin Soldered |

Reeds for Weaving Preparation

Reed for automatic and manual Warping Machines, "V" shaped Reeds and Reeds for Sizing Machines have also been our speciality, which is used extensively In the Weaving Preparatory process. These Reeds are supplied with special Hard Chroming to ensure smooth passing of yarns/knots and provide durability. Such Reeds can be designed as per the customers specifications. High Carbon Steel, Stainless Steel in both Flat & Round Dents, are the materials used in the manufacturing of these Reeds.